News

Note that the releases are accurate at the time of publication but may be subject to change without notice. This page shows only the most recent items. For the full archive of press releases please click "Search by category or year."

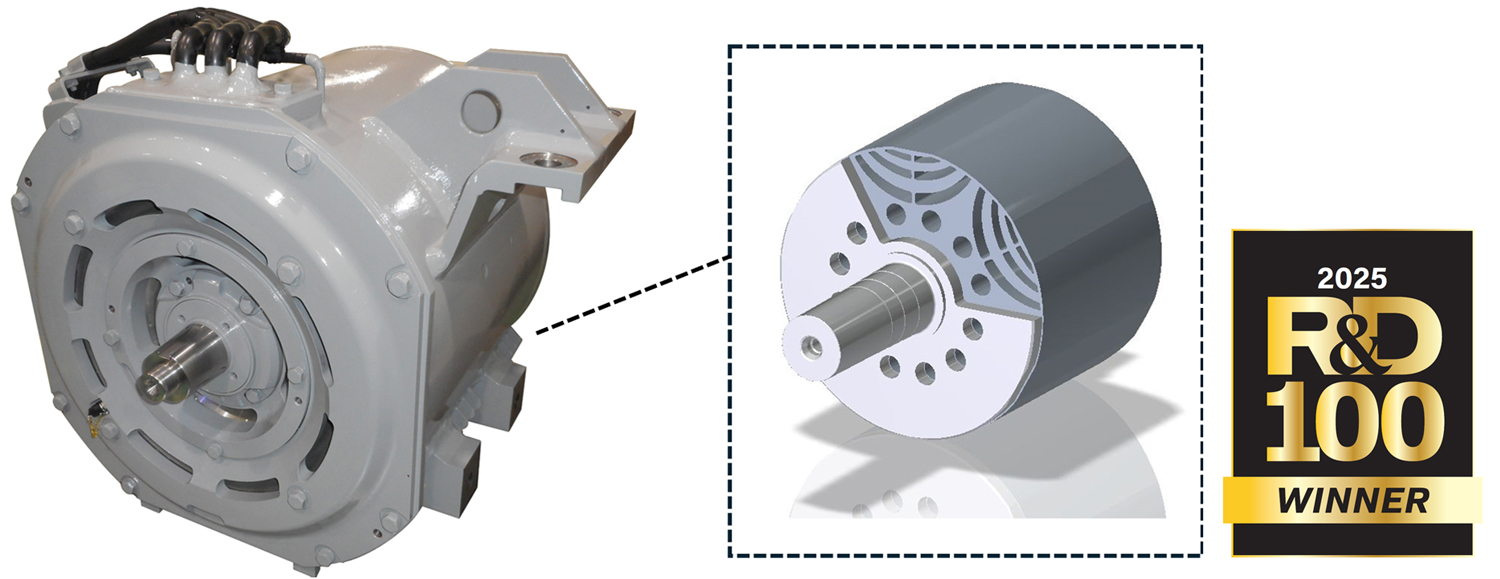

Mitsubishi Electric’s Railcar Motor System Wins R&D 100 Award

Synchronous reluctance motor (SynRM) and rendition of its internal rotor

TOKYO, October 3, 2025 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today that its energy- and resource-saving synchronous reluctance motor and inverter traction system (SynTRACS) for railcars has received a 2025 R&D 100 Award from the U.S. publication R&D World. This marks the 28th R&D 100 Award that Mitsubishi Electric has won to date.

The SynTRACS is equipped with the railway industry’s first synchronous reluctance motor (SynRM) to save energy and resources in railcars. The SynRM does not incorporate permanent magnets or rare earth materials in its rotor, and it is controlled with an inverter. Tests with actual railcars showed that energy consumption decreased by 18% compared to conventional high-efficiency induction motor systems, demonstrating significant energy savings.

Railroad operators are introducing vehicles and equipment that consume less energy to achieve greater sustainability. In November 2020, Mitsubishi Electric unveiled a new inverter-control technology for SynRMs that eliminates the need for permanent magnets and rare earth materials in the rotor. The technology achieves a maximum output of 450kW, making it one of the world’s largest SynRMs and suitable for a wide range of speeds required for railcars. It also reduces power loss by 50% compared to conventional high-efficiency induction motors.

From December 2021 to February 2022, Mitsubishi Electric installed the SynTRACS system in actual railcars for testing and confirmed that it reduces energy consumption by 18% compared to high-efficiency induction motor systems. The energy- and resource-saving system, which entered commercial mass production in the fiscal year that ended in March 2025, has been highly evaluated in the railway industry, contributing to its selection for the award.

Going forward, Mitsubishi Electric plans to leverage its advanced technological expertise to lead the development of next-generation motor systems for railcars.

Inquiry

-

Customer Inquiries

Advanced Technology R&D Center

Mitsubishi Electric CorporationFax: +81-6-6497-7285

Search by category or year of publication

There are no articles for the condition you specified.